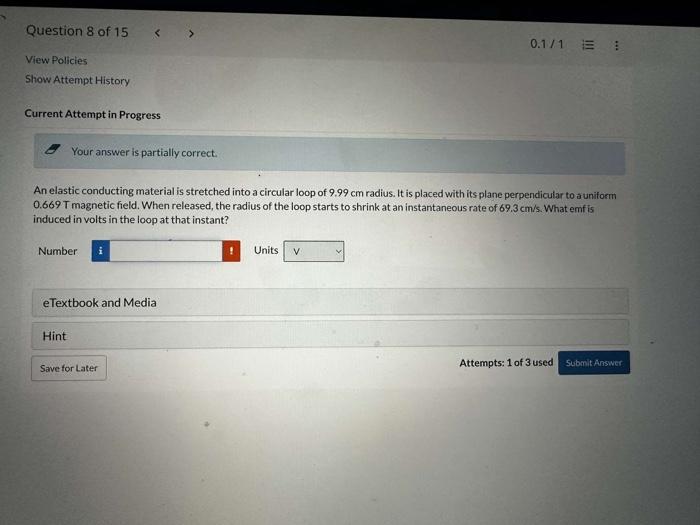

An elastic conducting material is stretched, revealing fascinating changes in its physical and electrical properties. This article delves into the stress-strain relationship, electrical conductivity alterations, and practical applications of these remarkable materials, providing a comprehensive overview of their significance in modern technology.

Stretching an elastic conducting material induces a unique interplay between mechanical stress and strain, altering its electrical conductivity. Understanding these changes is crucial for designing and optimizing devices that incorporate these materials.

Stress-Strain Relationship

When an elastic conducting material is stretched, the stress applied to the material is proportional to the strain experienced by the material. This relationship is known as the stress-strain relationship.

The stress-strain curve for an elastic conducting material is a graph that plots the stress (force per unit area) on the y-axis against the strain (change in length per unit length) on the x-axis. The slope of the stress-strain curve represents the elastic modulus of the material.

Elastic Modulus

The elastic modulus is a measure of the stiffness of a material. A material with a high elastic modulus will resist deformation more than a material with a low elastic modulus. The elastic modulus of an elastic conducting material is typically measured in gigapascals (GPa).

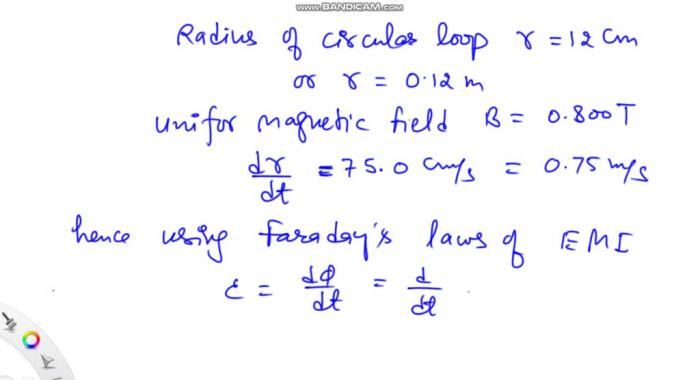

Electrical Conductivity Changes

When an elastic conducting material is stretched, its electrical conductivity changes. This is because the stretching of the material causes the atoms in the material to move closer together, which increases the number of collisions between the atoms and the electrons flowing through the material.

The increase in collisions between the atoms and the electrons decreases the mean free path of the electrons, which in turn decreases the electrical conductivity of the material.

Implications for Applications

The changes in electrical conductivity that occur when an elastic conducting material is stretched have implications for applications. For example, these changes can be used to create sensors that measure strain or force.

Applications of Stretchable Conductors

Stretchable conductors are used in a variety of applications, including:

- Sensors: Stretchable conductors can be used to create sensors that measure strain or force. These sensors can be used in a variety of applications, such as wearable devices and medical devices.

- Actuators: Stretchable conductors can be used to create actuators that can change shape or position when an electrical current is applied. These actuators can be used in a variety of applications, such as robotics and soft robotics.

- Energy storage: Stretchable conductors can be used to create energy storage devices, such as batteries and supercapacitors. These devices can be used in a variety of applications, such as wearable devices and electric vehicles.

Advantages and Challenges

Stretchable conductors offer a number of advantages over traditional conductors. These advantages include:

- Flexibility: Stretchable conductors can be stretched and deformed without breaking. This makes them ideal for applications where flexibility is important, such as wearable devices and medical devices.

- Lightweight: Stretchable conductors are lightweight, which makes them ideal for applications where weight is a concern, such as aerospace applications.

- Low cost: Stretchable conductors can be manufactured at a low cost, which makes them a cost-effective option for a variety of applications.

However, stretchable conductors also face a number of challenges. These challenges include:

- Durability: Stretchable conductors can be damaged if they are stretched or deformed too much. This can be a problem for applications where the conductor will be subjected to a lot of wear and tear.

- Reliability: Stretchable conductors can be less reliable than traditional conductors. This is because the stretching and deformation of the conductor can cause the electrical properties of the conductor to change.

Manufacturing Techniques: An Elastic Conducting Material Is Stretched

There are a number of different methods for manufacturing stretchable conducting materials. These methods include:

- Solution processing: Solution processing is a method for manufacturing stretchable conducting materials by dissolving a conducting material in a solvent and then coating the substrate with the solution. The solvent is then evaporated, leaving behind a thin film of the conducting material.

- Vapor deposition: Vapor deposition is a method for manufacturing stretchable conducting materials by depositing a conducting material onto a substrate in a vacuum chamber. The conducting material is vaporized and then deposited onto the substrate.

- Electrospinning: Electrospinning is a method for manufacturing stretchable conducting materials by spinning a solution of a conducting material into a fine fiber. The fibers are then collected on a substrate.

Advantages and Disadvantages

Each of these manufacturing techniques has its own advantages and disadvantages. Solution processing is a relatively simple and inexpensive method, but it can be difficult to control the thickness and uniformity of the conducting film. Vapor deposition is a more expensive method, but it can produce high-quality conducting films with a controlled thickness and uniformity.

Electrospinning is a versatile method that can be used to produce a variety of different conducting materials, but it can be difficult to control the diameter and uniformity of the fibers.

Scalability and Cost-Effectiveness

The scalability and cost-effectiveness of these manufacturing techniques are important factors to consider when choosing a method for manufacturing stretchable conducting materials. Solution processing is a scalable and cost-effective method, but it may not be suitable for applications where the thickness and uniformity of the conducting film are critical.

Vapor deposition is a more expensive method, but it is more scalable and can produce high-quality conducting films with a controlled thickness and uniformity. Electrospinning is a versatile method that can be used to produce a variety of different conducting materials, but it may not be suitable for applications where the diameter and uniformity of the fibers are critical.

Future Developments

The field of stretchable conducting materials is rapidly developing. There are a number of emerging trends and advancements in this field, including:

- The development of new materials with improved electrical conductivity and mechanical properties.

- The development of new manufacturing techniques that are more scalable and cost-effective.

- The development of new applications for stretchable conducting materials.

Potential Applications, An elastic conducting material is stretched

Stretchable conducting materials have the potential to be used in a wide range of applications, including:

- Wearable devices: Stretchable conducting materials can be used to create wearable devices that are comfortable to wear and can conform to the body’s movements.

- Medical devices: Stretchable conducting materials can be used to create medical devices that are less invasive and more comfortable for patients.

- Energy storage: Stretchable conducting materials can be used to create energy storage devices that are lightweight and flexible.

- Soft robotics: Stretchable conducting materials can be used to create soft robots that are more agile and versatile than traditional robots.

Challenges and Opportunities

The development of stretchable conducting materials faces a number of challenges, including:

- The need for materials with improved electrical conductivity and mechanical properties.

- The need for manufacturing techniques that are more scalable and cost-effective.

- The need for applications that can take advantage of the unique properties of stretchable conducting materials.

However, there are also a number of opportunities for the development of stretchable conducting materials. These opportunities include:

- The development of new materials with improved properties.

- The development of new manufacturing techniques that are more scalable and cost-effective.

- The development of new applications that can take advantage of the unique properties of stretchable conducting materials.

Stretchable conducting materials have the potential to revolutionize a wide range of industries. By overcoming the challenges and seizing the opportunities, we can unlock the full potential of these materials.

Frequently Asked Questions

What is the significance of the elastic modulus in stretchable conducting materials?

The elastic modulus quantifies the material’s stiffness, indicating its resistance to deformation under stress. A higher elastic modulus implies a stiffer material that can withstand greater forces without significant stretching.

How does stretching affect the electrical conductivity of these materials?

Stretching can induce changes in the material’s microstructure, affecting the mobility and concentration of charge carriers. This can lead to either an increase or decrease in electrical conductivity, depending on the material’s properties and the applied strain.

What are some potential applications of stretchable conducting materials?

These materials find applications in flexible electronics, wearable devices, sensors, actuators, and biomedical devices, where stretchability and electrical conductivity are essential.